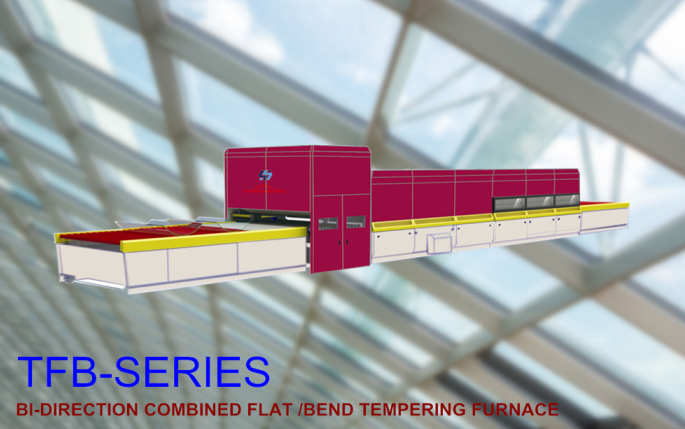

TFBL-SERIES BI-DIRECTION FLAT & BEND GLASS TEMPERING FURNACE (RIGID SHAFT BENDING)

Model | Max. Loading Area | Min.Glass Size | Thickness | Min.Radius |

(mm) | (mm) | (mm) | (mm) | |

LV-TFB1206L | 1200 x 600(for bent side) | 150 x 280 | 3 to 19 | more than 350 |

LV-TFB1608L | 1200 x 800(for bent side) | 150 x 280 | 4 to 19 | more than 450 |

LV-TFB2010L | 2010 x 1000(for bent side) | 150 x 280 | 4 to 19 | more than 500 |

LV-TFB2412L | 2440 x 1200(for bent side) | 150 x 280 | 4 to 19 | more than 550 |

LV-TFB2415L | 2440 x 1500(for bent side) | 150 x 320 | 5 to 19 | more than 700 |

LV-TFB3025L | 3000 x 2500(for bent side) | 150 x 320 | 5 to 19 | more than 1200 |

1. Machine Application:

For producing flat and bent tempered glass and thermal strengthened glass, which mainly used in the fields of architecture (doors, windows), shower room, home appliance, garden fence, elevator, furniture, side window of car, etc.

2. Main Technical Features:

2.1. Automatic arc-adjustment without any mould. It has exact formation and good roundness, which suitable for various radius.

2.2. Glass curvature is automatically controlled. The whole process is of automatic control and automatic diagnosis with friendly man-machine interface.

2.3. Helix matrix structure for heating oven, which can control the temperature of each area independently.

2.4. Full closed heating oven and high quality Insulating materials with top performance which can ensure a minimum power consumption and uniform oven temperature.

2.5. Fault diagnosis system for the heating elements.

2.6. Advanced & specially designed high-temperature convection fans shall be applied in convection system to eliminate electro-magnetic vibration. And there is no need the water cooling system. Also, it is very easy to make the maintenance and repairment.

2.7. For the force convection fans, If power off, there is small generator providing power to convection fan which could avoid any damage because of high temperature

2.8. PID temperature control,

2.9. Preventive function for the wrong operation

2.10. Synchronous and asynchronous running of each section

2.11. Power monitoring function

2.12. Suitable for processing clear float glass, patterned glass, reflective glass, low-e glass, etc.

2.13. Standard for processed products: GB15763.5, GB9656, EN12150-1:2000, ECER-43, ANSIZ97.1, etc.